Backup power systems in most facilities are sized to carry a subset of the total building load. These must be prioritized to ensure that the most important loads will be connected first, such as life-safety loads that enable people to exit a building during an emergency. Thereafter, legally required loads are supplied with backup power, and then optional loads may be added to accommodate a facility’s operating objectives. For more information on the prioritization of loads, review the ASCO Power Technologies document entitled National Electrical Code Requirements for Emergency Power Transfer Switching.

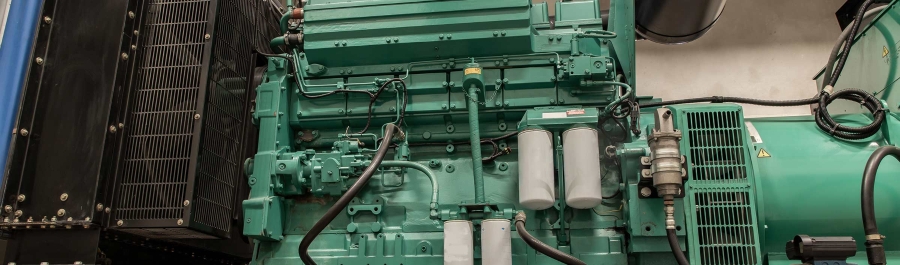

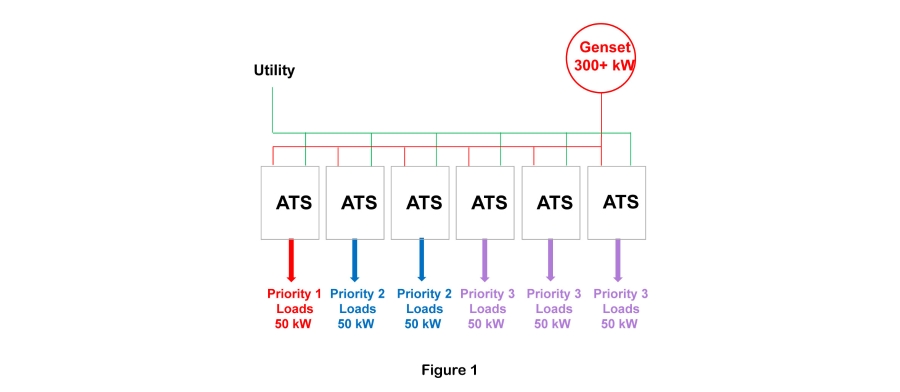

If a facility were to provide enough capacity to carry every load, it might use a system like the one shown in Figure 1. Six transfer switches each supply up to 50 kW of power, and thus requires a generator rated 300+ kW.More Load. Less Generator

However, in some applications, it is unlikely that every circuit will continually need to supply the maximum possible load. For example, refrigeration equipment must keep stored goods below a maximum temperature. Because the cold storage equipment is insulated, it is likely that the refrigeration equipment cycles on and off to maintain the required temperature. Likewise, HVAC equipment may cycle to keep room temperatures above or below specific set points. In either case, the load equipment does not need to run continuously. This provides an opportunity to use the corresponding generation capacity for another purpose.

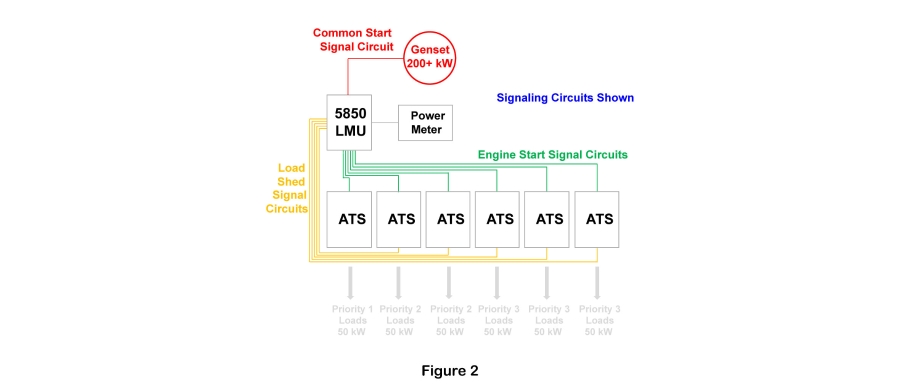

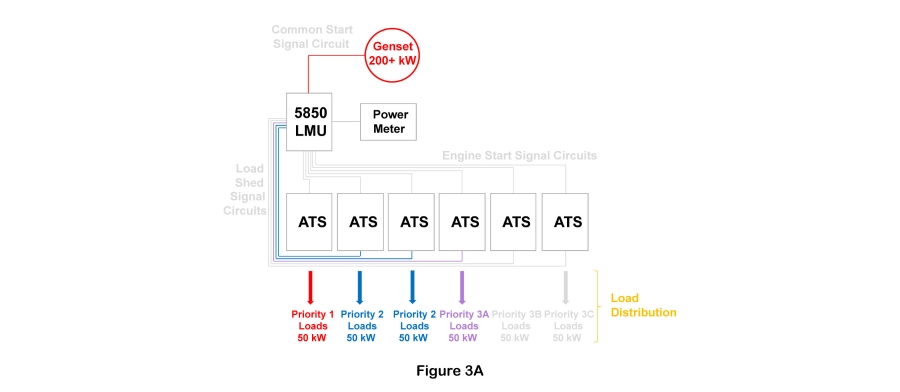

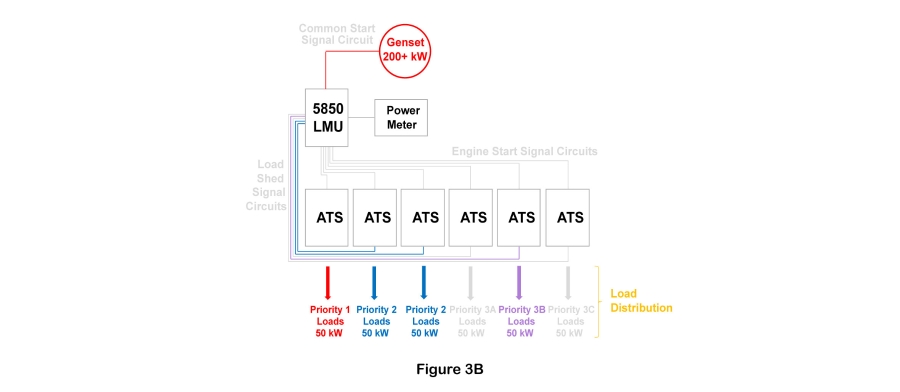

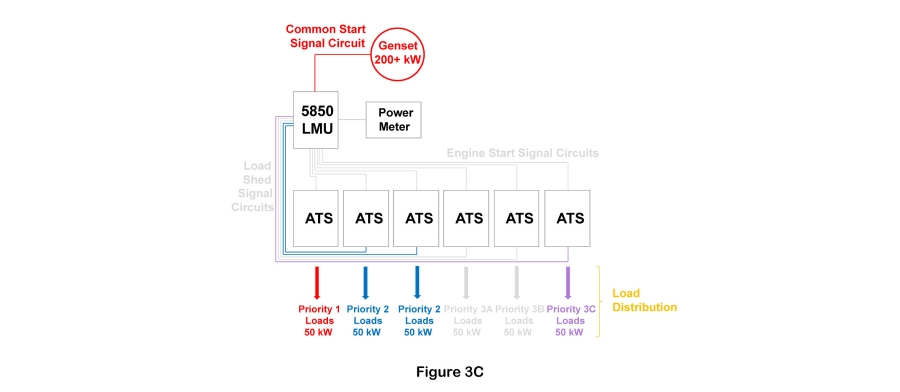

Where the operation of loads is cyclical, backup systems can be provisioned to direct power to load circuits in a sequence that optimizes the use of generator capacity. This is done by adding load shed circuits to all the Priority 2 and Priority 3 transfer switches in our example facility, as shown in Figure 2.

In multiple generator systems, this type of sequencing can be accomplished through the paralleling switchgear that is used to synchronize the power sources. In single-generator systems, this can be accomplished simply by using an ASCO 5850 Load Management Unit (LMU). Using measured load values from a power meter, the LMU evaluates the available generator capacity and optimizes its use by adding and shedding loads according to real-time demand. It does so by operating the corresponding transfer switches. It also can be programmed to operate transfer switches to direct power to cyclic loads in sequences that optimize the usage of generator capacity. This enables a facility to service cyclic loads with a smaller generator, or to service additional loads with an existing generator.

The ASCO 5850 Load Management Unit brings load management features to Automatic Transfer Switch applications. The following assets provide a full description of its capabilities, operation, and features:

White Paper - Basic Load Management Sequences Using ATSsData Sheet - ASCO 5800 SERIES Load Management Units

Product Video - ASCO 5800 SERIES Load Management Unit

To learn more about the potential need to extend backup power to cooling systems, refer to the following assets:

Application Video - Back Up Power Solutions for Residential Healthcare FacilitiesTechnical Brief - Risks from Concurrent Heatwaves and Power Outages