Transfer switches are critical to powering life-safety and legally required systems as well as mission-critical loads. UL1008 – Standard for Safety – Transfer Switch Equipment specifies the safety and endurance tests for verifying that transfer switches offer the highest levels of reliability and power availability. This article highlights important aspects of UL 1008 testing.

Highlights of UL 1008 Electrical Testing

Because a transfer switch is always connected to a power source, it must be capable of carrying its rated amount of current continuously. When faults occur, a transfer switch must carry the resulting current until it is cleared by a circuit breaker or fuse. If a transfer switch instead opened when faults occurred, it would leave loads without power even when power is restored to the facility. For the same reason, a transfer switch must also be able to reliably close on fault currents.

Manufacturers design generator transfer switches to provide specific service and fault current capabilities. To verify them, UL 1008 tests the ability of transfer switches to withstand and close on fault currents. The procedures required to verify corresponding ratings and functionality under fault conditions include the Withstand Test, the Closing Test, and the Dielectric Voltage Withstand Test.

Withstand Test

A transfer switch with closed main contacts is subjected to a short-circuit current of 20 to 50 times its service rating. More specifically, switches rated up to 100, up to 400, and greater than 400 Amps must respectively withstand minimum currents of 5,000 Amps, 10,000 Amps, and current at least 20 times the nominal switch ampacity (but not less than 10,000 Amps) until the current is cleared by an upstream fuse or breaker. The power factor must not exceed 0.50 for currents up to 10,000 Amps, 0.30 for currents up to 20,000 Amps, and 0.20 for currents exceeding 20,000 Amps.

Closing Test

Transfer switches must also be able to close on fault currents until cleared by an upstream protective device. Consequently, the withstand test is repeated, this time starting with the main contacts open. During this test, the contacts must close on and withstand a current with the same electrical parameters used for the Withstand Test.

Dielectric Voltage Withstand Test

Following these tests, an ac current of twice the rated voltage (but not less than 900V) must be applied to a transfer switch while voltage is measured at six types of locations within the device.

Passing Criteria

The switch must present the following conditions when the tests are complete:

• ability to close on untested contacts of the opposite power source circuit

• operability using whatever automatic or manual controls are provided

• no continuity between the terminals of the normal and alternate power source circuits

• no opening of doors on transfer switch enclosures

• cables cannot pull away from lugs and connectors

Optional Short-Time Tests

The aforementioned electrical tests require switches to carry a fault current until cleared by a protective device. However, many facilities employ selective coordination schemes using breakers that must withstand fault currents for specific durations. UL 1008 gives equipment manufacturers the option of demonstrating that a transfer switch can withstand and close on currents for times ranging from 0.1 to 0.5 seconds. If successful, manufacturers can mark a switch with corresponding Short-Time Ratings.

For more information about UL 1008 electrical rating tests, review the ASCO Power Technologies document entitled UL 1008 Transfer Switch Withstand and Closing Ratings. ASCO’s Selective Coordination Basics provides insight into coordinating overcurrent protection devices to minimize the scope of outages.

Performance Tests

Tests with profound implications for switch safety and longevity include the Overload Test, Endurance Test, and Temperature Rise Test.

Overload Test

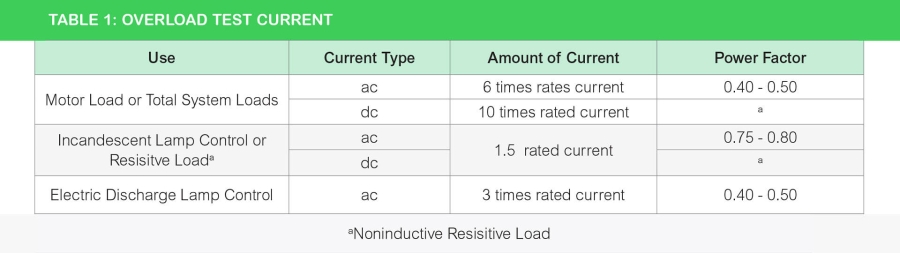

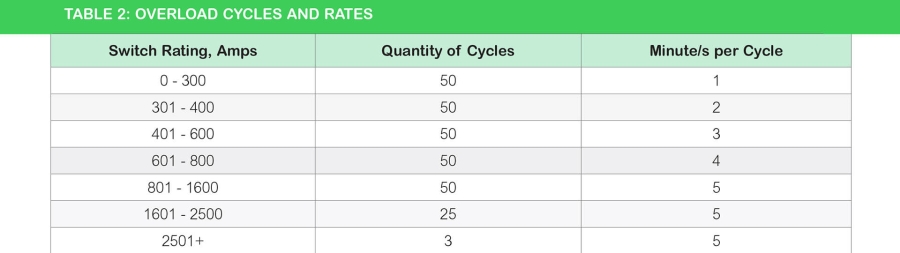

An overload test of a transfer switch requires cycling electrical load between power sources while the switch carries the overcurrents prescribed in Table 1. According to switch ampacity, it must carry these currents for the quantities of cycles listed in Table 2.

Highlights of UL 1008 Electrical Testing

Because a transfer switch is always connected to a power source, it must be capable of carrying its rated amount of current continuously. When faults occur, a transfer switch must carry the resulting current until it is cleared by a circuit breaker or fuse. If a transfer switch instead opened when faults occurred, it would leave loads without power even when power is restored to the facility. For the same reason, a transfer switch must also be able to reliably close on fault currents.

Manufacturers design generator transfer switches to provide specific service and fault current capabilities. To verify them, UL 1008 tests the ability of transfer switches to withstand and close on fault currents. The procedures required to verify corresponding ratings and functionality under fault conditions include the Withstand Test, the Closing Test, and the Dielectric Voltage Withstand Test.

Withstand Test

A transfer switch with closed main contacts is subjected to a short-circuit current of 20 to 50 times its service rating. More specifically, switches rated up to 100, up to 400, and greater than 400 Amps must respectively withstand minimum currents of 5,000 Amps, 10,000 Amps, and current at least 20 times the nominal switch ampacity (but not less than 10,000 Amps) until the current is cleared by an upstream fuse or breaker. The power factor must not exceed 0.50 for currents up to 10,000 Amps, 0.30 for currents up to 20,000 Amps, and 0.20 for currents exceeding 20,000 Amps.

Closing Test

Transfer switches must also be able to close on fault currents until cleared by an upstream protective device. Consequently, the withstand test is repeated, this time starting with the main contacts open. During this test, the contacts must close on and withstand a current with the same electrical parameters used for the Withstand Test.

Dielectric Voltage Withstand Test

Following these tests, an ac current of twice the rated voltage (but not less than 900V) must be applied to a transfer switch while voltage is measured at six types of locations within the device.

Passing Criteria

The switch must present the following conditions when the tests are complete:

• ability to close on untested contacts of the opposite power source circuit

• operability using whatever automatic or manual controls are provided

• no continuity between the terminals of the normal and alternate power source circuits

• no opening of doors on transfer switch enclosures

• cables cannot pull away from lugs and connectors

Optional Short-Time Tests

The aforementioned electrical tests require switches to carry a fault current until cleared by a protective device. However, many facilities employ selective coordination schemes using breakers that must withstand fault currents for specific durations. UL 1008 gives equipment manufacturers the option of demonstrating that a transfer switch can withstand and close on currents for times ranging from 0.1 to 0.5 seconds. If successful, manufacturers can mark a switch with corresponding Short-Time Ratings.

For more information about UL 1008 electrical rating tests, review the ASCO Power Technologies document entitled UL 1008 Transfer Switch Withstand and Closing Ratings. ASCO’s Selective Coordination Basics provides insight into coordinating overcurrent protection devices to minimize the scope of outages.

Performance Tests

Tests with profound implications for switch safety and longevity include the Overload Test, Endurance Test, and Temperature Rise Test.

Overload Test

An overload test of a transfer switch requires cycling electrical load between power sources while the switch carries the overcurrents prescribed in Table 1. According to switch ampacity, it must carry these currents for the quantities of cycles listed in Table 2.