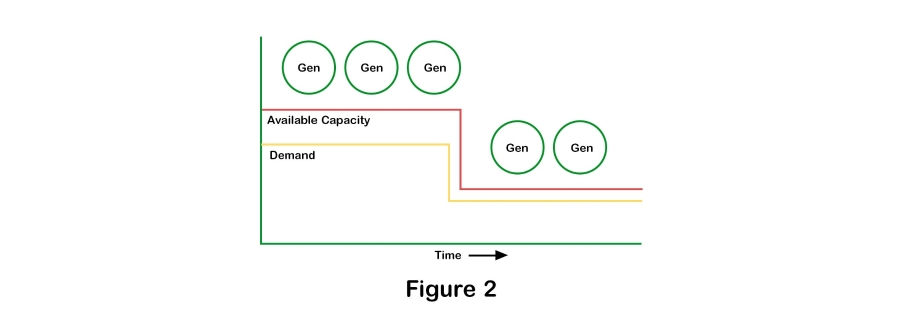

In a healthcare facility, certain HVAC systems may only need to be run long enough to keep temperatures in patient-occupied areas below specific thresholds. In a supermarket, refrigerator and freezer systems may only need to run a portion of each hour to prevent spoilage of stored goods. In either case, selectively connecting systems in different hospital wards or supermarket aisles in a defined sequence for prescribed time intervals may keep conditions within acceptable ranges, all while making backup power available to more systems. Using this strategy, a facility could be supplied by smaller or fewer generators than if it dedicated capacity to each load continuously. This again increases efficiency and reduces equipment cost, fuel usage, and resulting emissions. These arrangements can allow a facility to install smaller generation capacity when the appropriate load management sequence are properly planned.

Automated Reporting

In their service lives, most backup power systems will spend more time running for test and maintenance purposes than actually supplying power during outages. Equipping these systems with intelligent automatic reporting capabilities such as those offered with ASCO Critical Power Management Appliances (CPMA) can help reduce overall runtime. Here’s how it works.

Industry codes such as NFPA 110 require periodic testing involving specified amounts of load for specified runtimes. For instance, monthly tests of systems that use diesel generators must run for at least 30 minutes at a minimum of 30 percent of a genset’s nameplate output rating. Doing so results in a compliant test event, and in the absence of utility outages, the facility will undertake 12 of these tests in a year. These tests can be performed with the use of load banks, which can reliably and safely test facility generators. For more information about backup power testing codes, read Part 2 of ASCO’s NFPA 110 Overview.

But consider that the facility will likely experience utility outages during any given year. If an outage lasts 30 minutes and continuously requires a minimum of 30% of output capacity, it meets the requirements for a compliant test. Codes allow for data from such an event to be used for compliance purposes.

Facility’s provisioned with an ASCO CPMA will have recorded all of the data required from every backup power device, and can automatically generate a compliance report from the outage data in the time that it takes to read this article. If this type of outage occurs only twice each year, the facility may be able to cancel two of its planned test events, reducing its annual runtime for compliance testing by nearly 17 percent. This streamlines compliance activities, extends the service life of the equipment, and reduces costs and emissions.

ASCO devices that provide this reporting function include the 5701 8-Device Gateway, the 5702 Power Management Gateway, and the ASCO 5705 8-Device Annunciator. For more information on automated monitoring and reporting systems, see ASCO’s short article entitled Three Benefits of Automated Critical Power Reporting and its white paper entitled The Value of Automated Power Compliance Reporting.