The Need to Test Backup Power Systems

There are multiple reasons why facilities implement a programs of comprehensive backup power systems testing. Among them, it is simply necessary to test backup power systems periodically to verify that they remain able to provide emergency power whenever outages occur on the normal power source. Without routine testing, there is simply no means to ensure that backup power systems can function properly when needed. And they will be needed … read Utility Reliability and Critical Backup Power to review why.

Not only is routine testing a best practice, it can also be required by industry codes. For instance, NFPA 99 – Health Care Facilities Code calls for healthcare facilities to implement a regular program of testing in accordance with NFPA 110 – Standard for Emergency and Standby Power Systems, which specifies minimum test requirements for backup power systems. NFPA 70 – National Electrical Code requires testing in accordance with the equipment manufacturer directions as well as the authorities having jurisdiction, and refers to NFPA 99 for guidance on periodic testing. In the USA, routine testing is must be evidenced for hospitals with Joint Commission accreditation, which is a condition for reimbursement from programs such as Medicare and Medicaid. You can learn more about NFPA 110 in Part 1 and Part 2 of the ASCO White Paper entitled NFPA Overview. More information about the NEC can be found in National Electrical Code Requirements for Emergency Power Transfer Switching and 2020 NEC Changes for Backup Power.

Medical facilities are not the only organizations subject to backup testing requirements. Data centers and other mission-critical facilities are also subject to NFPA 110 provisions. In addition, The Commission on Accreditation for Law Enforcement Agencies (CALEA®) credentials public safety programs and organizations, and maintains standards for preparedness for regulated facilities. In this context, it is easy to understand the importance of adequate generator testing. During a public safety event or natural disaster, the implications of failed backup power systems at an emergency call center, a data center that is essential for commerce, a facility that supports security intelligence, or at a prison could be profound. Article 708 of the NEC requires periodic testing of Critical Operations Power Systems at these systems as well. In short, if the risks of power interruption were enough to justify the installation of a backup power system, those same risks warrant regular backup system tests.

Executing Tests

Recording Test Data

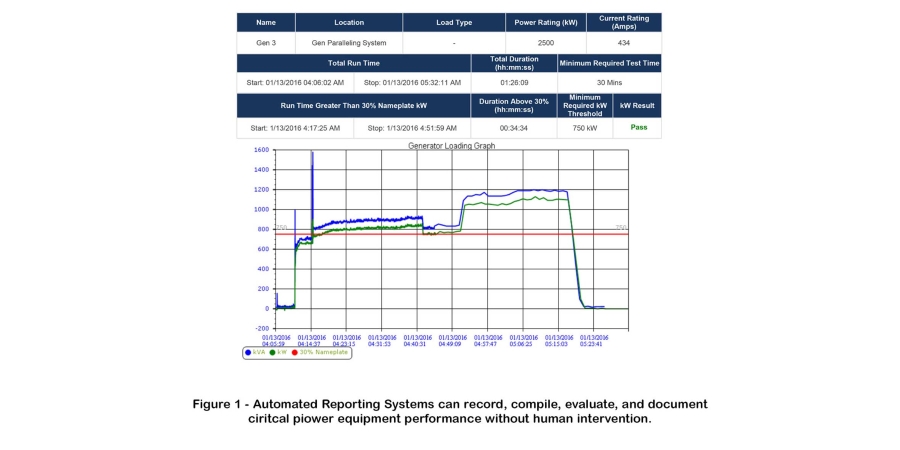

When an emergency power system is tested, pertinent information must be recorded, including the time that normal power was disrupted, the time that a generator start signal was issued, the time that each transfer switch successfully transferred to a backup power source, and the time of retransfers to the normal power source. At the generator, the total load must be recorded as a percentage of rated generator capacity over the time the test is conducted.

To complete a test, all of the necessary data must be recorded. When a system is simply configured – for example, and single generator and a pair of transfer switches, the necessary data might be manually recorded by querying the controllers on each device. However, this becomes impractical with more complex systems. The amount of labor involved to capture the necessary data from systems comprised of a half dozen generators, one or more paralleling switchgear systems, and dozens of transfer switches is substantial. If manually recorded, the process is prone to human error.

To automate the process, the controllers of power equipment devices or connected data logging devices record and store the needed data. Timestamps are compiled for key events such as onset of outage, duration of outage, the elapsed time to bring acceptable power online from gensets, and the elapsed transfer time for every transfer switch.

Evaluating Test Results

NFPA 110 specifies minimum generator loading levels and runtime durations for various tests. The NEC specifies that backup power must be supplied to loads within prescribed intervals, specifically within 10 and 60 seconds for life-safety and legally required loads, respectively. If a test event does not meet these requirements, the facility will not achieve passing criteria. For instance, if the load drops below 30% of genset capacity during a 30-minute run of a monthly operating test, the test data are non-compliant.

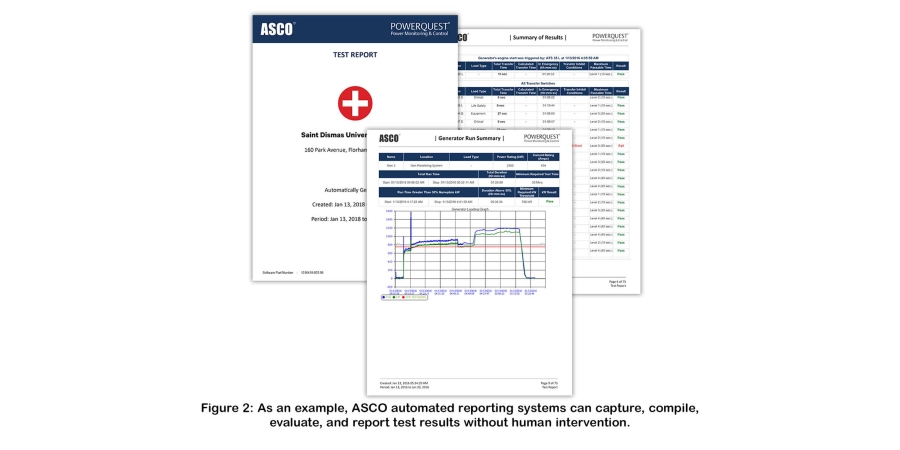

To demonstrate compliance, the data recorded during the test must be compared with the performance criteria presented by industry codes. Again, doing this manually is time-consuming and prone to error. Instead, automated reporting systems can be configured to compare the recorded data for each power device with set points for a measured values. Programs can compute delays and elapsed times for switch transfers and validate the run time and loading of gensets automatically and quickly, without human intervention (Figure 1).