“Aren’t they all power breakers?”

To the uninitiated, the term “power breaker” would seem to apply to any circuit breaker. To those more familiar, the term focuses on a range of low voltage circuit breakers. Because breaker nomenclature can seem complex, this article reviews the terms that describe commonly used in low-voltage, backup power systems.

Molded Case Circuit Breakers

Some breaker types are named for the manner in which they are constructed. The term molded case circuit breaker identifies a breaker that is assembled as an integral unit within a supportive enclosure of insulating material … typically, a molded plastic case. Within this category, breakers are differentiated by their trip mechanisms. There are two principle types - thermal-magnetic and solid-state.

Thermal-Magnetic Trip Mechanism

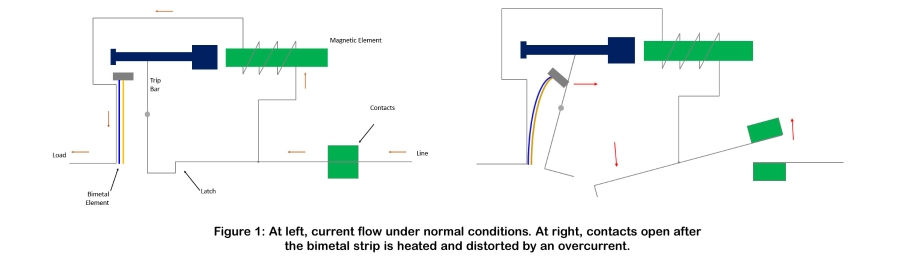

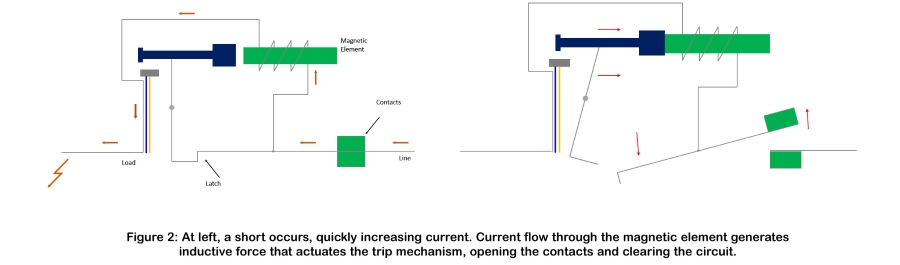

Thermal-magnetic circuit breakers can be tripped open by either of two actuators, a thermal device that responds to prolonged overcurrents, and a magnetic device that responds to sudden short circuit currents.

The thermal device usually consists of a bimetallic element alongside a conductor. When overcurrents occur, resistive heating causes the metals in the element to heat at differing rates, resulting in differential expansion that causes the component to bend. When the bend is sufficient, it displaces a trip bar that opens the breaker contacts, stopping the flow of current through the circuit. The concept is shown in Figure 1.

To the uninitiated, the term “power breaker” would seem to apply to any circuit breaker. To those more familiar, the term focuses on a range of low voltage circuit breakers. Because breaker nomenclature can seem complex, this article reviews the terms that describe commonly used in low-voltage, backup power systems.

Molded Case Circuit Breakers

Some breaker types are named for the manner in which they are constructed. The term molded case circuit breaker identifies a breaker that is assembled as an integral unit within a supportive enclosure of insulating material … typically, a molded plastic case. Within this category, breakers are differentiated by their trip mechanisms. There are two principle types - thermal-magnetic and solid-state.

Thermal-Magnetic Trip Mechanism

Thermal-magnetic circuit breakers can be tripped open by either of two actuators, a thermal device that responds to prolonged overcurrents, and a magnetic device that responds to sudden short circuit currents.

The thermal device usually consists of a bimetallic element alongside a conductor. When overcurrents occur, resistive heating causes the metals in the element to heat at differing rates, resulting in differential expansion that causes the component to bend. When the bend is sufficient, it displaces a trip bar that opens the breaker contacts, stopping the flow of current through the circuit. The concept is shown in Figure 1.