Diesel is presently the most common fuel used by facilities for generating backup power on-site. Rising concern for climate and sustainability issues has increased interest in using natural gas for this purpose. This article summarizes the advantages and disadvantages of each fuel and describes applications where each can be used to an end user’s advantage.

Fuels and Their Availability

There are good reasons why diesel fuel is the most common type for onsite generators. It is readily available throughout many regions of the world for delivery into onsite storage tanks that supply generators. Diesel engines provide powerful and reliable service, and there is a ready workforce with skills needed to install, maintain, and service diesel-powered generator sets.

Although its use is less common than diesel, natural gas is also used to power backup generators. In most industrialized areas, natural gas is available through utility pipeline networks that deliver gas continually. As a result, utility-supplied natural gas offers greater convenience and a streamlined user experience – no one has to schedule deliveries or install and manage tankage. Conversely, natural gas is not available in many rural areas, and may not be available in sufficient quantity at certain sites served by utilities.

In a limited number of installations, waste methane is available for use. Essentially similar to commercial natural gas, facilities located near landfills, wastewater sludge digesters, and other processes involving biodegradation can produce methane for power generation. This is a beneficial use of a resource that might otherwise be dissipated into the atmosphere, where it could contribute to the accumulation of greenhouse gases. Factors that impact methane use for backup power are similar to those for natural gas.

Sustainability initiatives sometimes involve discussions about using hydrogen in operations typically powered by fossil fuels. While a potential “hydrogen economy” has yet to materialize, hydrogen is used in some industrial processes as a fuel stock, an option that could have application in backup power generation, including natural gas-fired gensets. As more alternative sources of power are connected to utility grids, the effects of energy overproduction have the potential to destabilize their operation. The production of hydrogen using excess power could be used to stabilize electric utility grids. If such practice became common, hydrogen could be blended into natural gas distributed by utilities to further reduce greenhouse gas emissions, or generated at sites where alternate energy sources are present.

Energy Density and Engine Performance

The internal combustion engines that power generators operate by burning fuel gases. For a natural gas engine supplied by a utility, the fuel is delivered into the engine in a gaseous state. For a diesel engine, its fuel system vaporizes or atomizes liquid fuel before introducing it into the combustion chambers of engines. The amount of energy contained in a specific volume of each fuel differs, with diesel fuel presenting a greater amount of energy per unit than natural gas. Consequently, diesel engines have historically offered a better response to changes in load than equivalent natural gas engines. Natural gas engines have historically offered less ability to respond quickly to load changes. This can affect how generators accept load increases.

Block Loading Capability

Adding a large electrical load to a genset, an action known as block loading, suddenly will cause it to slow, instantly decreasing the frequency and voltage of the current it produces. A genset will attempt to recover by increasing throttle to introduce more fuel and produce more power. Engines with sufficient reserve power and responsiveness can recover properly from the instant application of large loads. Engines with insufficient responsiveness can produce voltage and frequency excursions beyond acceptable levels for longer-than-accepted durations. In extreme cases, an engine can stall, resulting in an outage.

Genset Startup

Engine responsiveness also plays a role in the starting abilities of engine-generators. To supply acceptable backup power, a genset must accelerate from a cold start condition to full operating speed as quickly as possible. This is especially important for critical loads. For instance, Article 700 of the National Electrical Code requires backup power to be available for life-safety systems of regulated facilities within 10 seconds of the occurrence of an outage. Because natural gas offers a lower energy density than diesel, natural gas engines can be less capable of responding to block loading than diesel engines.

The above-described tendencies have historically been true, and diesels have routinely been selected for this application. Nevertheless, some of the newest natural gas engine-generators have been designed to provide greater responsiveness for better performance when started and block-loaded.

Emissions by Fuel Type

Diesel and natural gas both emit pollutants when burned. Both emit carbon dioxide, a greenhouse gas associated with global warming. However, natural gas emits less carbon dioxide (CO2) and particulate matter than diesel engines. For these reasons and more, natural gas has a reputation as a clean-burning fuel, and it is used in schemes designed to limit environmental impact.

While all of the preceding information is true, the most modern diesel engines run cleaner than prior designs. These can employ cleaner combustion processes as well as a host of pollution control technologies such as diesel particulate filters, exhaust gas recirculation features, and fuel additives that alter combustion chemistry.

Options for Multi-Generator Systems

Because of their performance characteristics and the widespread availability of diesel fuel, diesel-powered generators are the most popular for emergency power, particularly where there is only a single genset. Nevertheless, natural gas-powered generators are successfully used in a variety of applications. They can make sense where generators will see extended planned runtimes. These applications include facilities where two or more generators are used to provide adequate capacity, redundancy, and resilience.

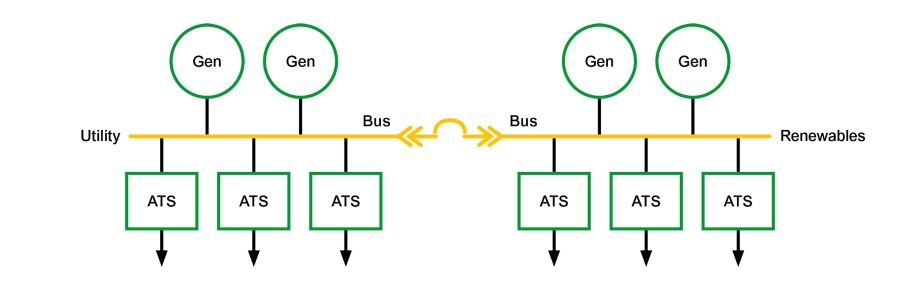

Most facilities with more than one generator distribute power using a single power distribution system. Doing so requires genset synchronization whenever more than one unit is connected to the system. This is accomplished using paralleling switchgear, which synchronizes and connects multiple power sources and loads to one or more sections of the electrical bus. For more information about the design and operation of these systems, see the resources at the end of this article.

Fuels and Their Availability

There are good reasons why diesel fuel is the most common type for onsite generators. It is readily available throughout many regions of the world for delivery into onsite storage tanks that supply generators. Diesel engines provide powerful and reliable service, and there is a ready workforce with skills needed to install, maintain, and service diesel-powered generator sets.

Although its use is less common than diesel, natural gas is also used to power backup generators. In most industrialized areas, natural gas is available through utility pipeline networks that deliver gas continually. As a result, utility-supplied natural gas offers greater convenience and a streamlined user experience – no one has to schedule deliveries or install and manage tankage. Conversely, natural gas is not available in many rural areas, and may not be available in sufficient quantity at certain sites served by utilities.

In a limited number of installations, waste methane is available for use. Essentially similar to commercial natural gas, facilities located near landfills, wastewater sludge digesters, and other processes involving biodegradation can produce methane for power generation. This is a beneficial use of a resource that might otherwise be dissipated into the atmosphere, where it could contribute to the accumulation of greenhouse gases. Factors that impact methane use for backup power are similar to those for natural gas.

Sustainability initiatives sometimes involve discussions about using hydrogen in operations typically powered by fossil fuels. While a potential “hydrogen economy” has yet to materialize, hydrogen is used in some industrial processes as a fuel stock, an option that could have application in backup power generation, including natural gas-fired gensets. As more alternative sources of power are connected to utility grids, the effects of energy overproduction have the potential to destabilize their operation. The production of hydrogen using excess power could be used to stabilize electric utility grids. If such practice became common, hydrogen could be blended into natural gas distributed by utilities to further reduce greenhouse gas emissions, or generated at sites where alternate energy sources are present.

Energy Density and Engine Performance

The internal combustion engines that power generators operate by burning fuel gases. For a natural gas engine supplied by a utility, the fuel is delivered into the engine in a gaseous state. For a diesel engine, its fuel system vaporizes or atomizes liquid fuel before introducing it into the combustion chambers of engines. The amount of energy contained in a specific volume of each fuel differs, with diesel fuel presenting a greater amount of energy per unit than natural gas. Consequently, diesel engines have historically offered a better response to changes in load than equivalent natural gas engines. Natural gas engines have historically offered less ability to respond quickly to load changes. This can affect how generators accept load increases.

Block Loading Capability

Adding a large electrical load to a genset, an action known as block loading, suddenly will cause it to slow, instantly decreasing the frequency and voltage of the current it produces. A genset will attempt to recover by increasing throttle to introduce more fuel and produce more power. Engines with sufficient reserve power and responsiveness can recover properly from the instant application of large loads. Engines with insufficient responsiveness can produce voltage and frequency excursions beyond acceptable levels for longer-than-accepted durations. In extreme cases, an engine can stall, resulting in an outage.

Genset Startup

Engine responsiveness also plays a role in the starting abilities of engine-generators. To supply acceptable backup power, a genset must accelerate from a cold start condition to full operating speed as quickly as possible. This is especially important for critical loads. For instance, Article 700 of the National Electrical Code requires backup power to be available for life-safety systems of regulated facilities within 10 seconds of the occurrence of an outage. Because natural gas offers a lower energy density than diesel, natural gas engines can be less capable of responding to block loading than diesel engines.

The above-described tendencies have historically been true, and diesels have routinely been selected for this application. Nevertheless, some of the newest natural gas engine-generators have been designed to provide greater responsiveness for better performance when started and block-loaded.

Emissions by Fuel Type

Diesel and natural gas both emit pollutants when burned. Both emit carbon dioxide, a greenhouse gas associated with global warming. However, natural gas emits less carbon dioxide (CO2) and particulate matter than diesel engines. For these reasons and more, natural gas has a reputation as a clean-burning fuel, and it is used in schemes designed to limit environmental impact.

While all of the preceding information is true, the most modern diesel engines run cleaner than prior designs. These can employ cleaner combustion processes as well as a host of pollution control technologies such as diesel particulate filters, exhaust gas recirculation features, and fuel additives that alter combustion chemistry.

Options for Multi-Generator Systems

Because of their performance characteristics and the widespread availability of diesel fuel, diesel-powered generators are the most popular for emergency power, particularly where there is only a single genset. Nevertheless, natural gas-powered generators are successfully used in a variety of applications. They can make sense where generators will see extended planned runtimes. These applications include facilities where two or more generators are used to provide adequate capacity, redundancy, and resilience.

Most facilities with more than one generator distribute power using a single power distribution system. Doing so requires genset synchronization whenever more than one unit is connected to the system. This is accomplished using paralleling switchgear, which synchronizes and connects multiple power sources and loads to one or more sections of the electrical bus. For more information about the design and operation of these systems, see the resources at the end of this article.