Industry standards specify performance tests that must be completed to verify the safety and functionality of transfer switches. Learning about observed effects of repetitive tests can underscore the value of installing thoroughly tested equipment in end-use facilities. This paper summarizes the need for, nature of, and effects seen during switching tests, and discusses how the results benefit end users.

POSSIBLE TRANSFER SWITCH FAILURE MODES

In order to understand the need for transfer switch switching tests, it is best to review some of the possible ways that inadequately tested or mis-used transfer switches could fail. Three potential problems could include (1) degradation of transfer mechanism performance, (2) degradation of contact materials, and (3) inability to extinguish the arc produced by contact during switching.

Degradation of Transfer Mechanism Performance

Transfer switch mechanism operation can degrade in ways that cause performance or reliability issues. The most profound mode is if a switch mechanism were to seize, preventing operation; or, more likely, be bound or restricted in some fashion that causes it to move less freely. Causes could include improper design or a manufacturing defect. Thorough mechanical testing is necessary to verify that a switch can repeatedly and reliably operate when subjected to foreseeable stresses. UL 1008 specifies testing transfer switches under severe conditions for extensive cycles to assure that designs are safe and adequate.1

Degradation of Contacts

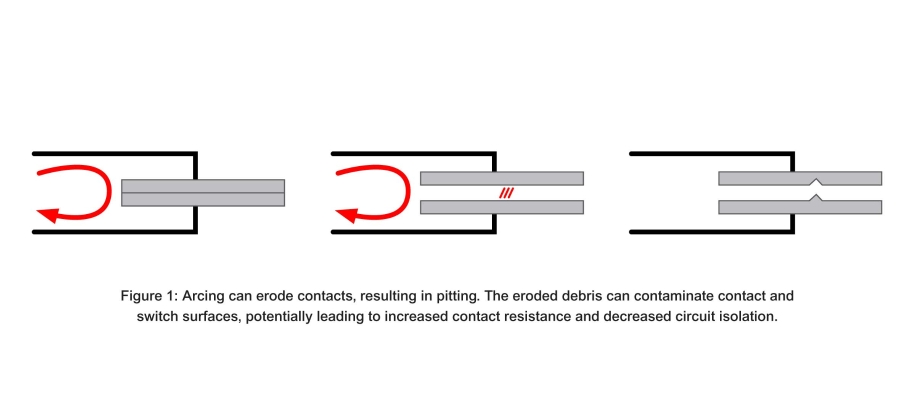

Contacts in a transfer switch mechanism are composed of alloys of metallic and refractory materials. When repeatedly opened and closed, arcing erodes the contact surfaces, which increase electrical resistance across the contacts (Figure 1). Contact erosion also reduces the contact force as a function of reduced spring deflection.

POSSIBLE TRANSFER SWITCH FAILURE MODES

In order to understand the need for transfer switch switching tests, it is best to review some of the possible ways that inadequately tested or mis-used transfer switches could fail. Three potential problems could include (1) degradation of transfer mechanism performance, (2) degradation of contact materials, and (3) inability to extinguish the arc produced by contact during switching.

Degradation of Transfer Mechanism Performance

Transfer switch mechanism operation can degrade in ways that cause performance or reliability issues. The most profound mode is if a switch mechanism were to seize, preventing operation; or, more likely, be bound or restricted in some fashion that causes it to move less freely. Causes could include improper design or a manufacturing defect. Thorough mechanical testing is necessary to verify that a switch can repeatedly and reliably operate when subjected to foreseeable stresses. UL 1008 specifies testing transfer switches under severe conditions for extensive cycles to assure that designs are safe and adequate.1

Degradation of Contacts

Contacts in a transfer switch mechanism are composed of alloys of metallic and refractory materials. When repeatedly opened and closed, arcing erodes the contact surfaces, which increase electrical resistance across the contacts (Figure 1). Contact erosion also reduces the contact force as a function of reduced spring deflection.