When selecting power transfer switches, consideration is often focused on items such as withstand and closing ratings, transition mode, neutral management, and more. During the selection process, however, it is beneficial to consider additional practical aspects that can make it easier to install and live with a finished system. Cable bend space is one of those aspects. Here are two reasons why.

Reason 1: Cable Properties

To facilitate installation through facilities and into equipment, electrical power cables are designed to be flexed. However, flexing them too far can damage elements of a cable, such as shielding, insulating materials, and even conductors. The amount of flex that a cable can tolerate depends on diameter, conductor characteristics, and other factors. Consequently, industry codes specify minimum bend radii for specific types and sizes of cables. These need to be observed to ensure reliable service.

Code Guidance

In many industry and regional standards, minimum radii are stated as a function of cable diameter. In the National Electrical Code®, Article 312 addresses cable bend space for power equipment in cabinets where conductors enter or exit through the wall of an equipment enclosure in Table 312.6(B). For example, it specifies a minimum space for 300 AWG or kcmil cable as follows: 1

• 10 inches (254 millimeters) for terminals served by one or two conductors

• 11 inches (279 millimeters) for terminals served by three conductors

• 12 inches (279 millimeters) for terminals served by four or more conductors

Reason 2: Ease of Installation

A second reason to consider cable bend space is that inadequate space can make cables more difficult to install and equipment harder to service. For a transfer switch of a specific physical size, larger diameter cables will require more bending space, which could make it more difficult to route cables to equipment terminals. The extent of this problem depends on factors including the ampacity of the switch relative to the overall size of its enclosure, available pathways for cable entry, and the amount of space within a particular transfer switch for managing cable and accommodating cable bends.

Enclosure Size

In some transfer switch product ranges, a specific ampacity may be offered by different models with differing overall sizes. For instance, in ASCO’s product lines, an ampacity of 600 Amps can be provided by either J-frame or H-frame transfer switches. Because the H-frame uses a larger chassis and enclosure, there typically will be more space for managing cables. Conversely, the J-frame offers, among other differences, a smaller footprint for the same ampacity. Manufacturers may offer larger enclosures or attachable pull boxes to provide additional cable bend space. Where a switch of a specific ampacity is available in only one size, a switch of higher ampacity could be selected to obtain more space for bending and managing power cables.

Available Pathways

Switches may offer options for routing power cables through the top and/or bottom of switch enclosures and locating terminals along the front or rear. The range of available pathways will vary by transfer switch manufacturer, model, and size. For instance, the above-referenced J-frame transfer switch offers terminals for front connection only, while the larger H-frame model provides options for either front-connected or rear-connected configurations. Where a necessary configuration is unavailable, some manufacturers offer custom engineering services. Read the ASCO document entitled Benefits of Custom-Engineered Transfer Switches for additional information. 2

Available Volume

Larger transfer switches generally offer more space for bending and routing cables. Nevertheless, applications involving many cables can present unique challenges. Where cables are very dense, it may be difficult to coordinate their respective bending, routing, and termination. Once installed, it also may be difficult to access them for visual or thermal inspection of connections, tightening of cable connections, or for service of any nearby components. To alleviate cable crowding, pull boxes may be added to the sides of equipment frames to provide more space.

Installation Considerations

Cable bend space should be considered for both new installations and system upgrades. Providing sufficient room to bend, route, and terminate cables can streamline both new installations and retrofits. If power system upgrades or expansions may be needed, then providing extra room could mean the difference between future adaptability or obsolescence.

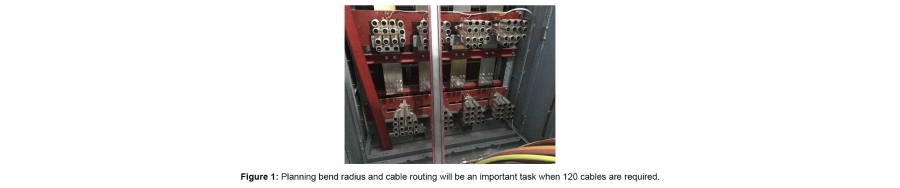

Notably, specifiers also need to consider the adequacy of the aforementioned NEC requirements. Table 312.6(B) provides bend space values for applications that use one through “4+” cables per terminal. Without further consideration, this guidance could prove insufficient. Figure 1 shows the terminals for an uninstalled 4000 Amp transfer switch configured with lugs for fifteen 300 kcmil power cables per terminal. Because this is a four-pole switch, 120 cables will be installed on the back of this device. The NEC specified bend space may be insufficient for such a large number of cables. Consequently, specifiers can ensure that cable space and routing issues will not be problematic by consulting transfer switch providers and installers before finalizing a cable termination configuration.

Reason 1: Cable Properties

To facilitate installation through facilities and into equipment, electrical power cables are designed to be flexed. However, flexing them too far can damage elements of a cable, such as shielding, insulating materials, and even conductors. The amount of flex that a cable can tolerate depends on diameter, conductor characteristics, and other factors. Consequently, industry codes specify minimum bend radii for specific types and sizes of cables. These need to be observed to ensure reliable service.

Code Guidance

In many industry and regional standards, minimum radii are stated as a function of cable diameter. In the National Electrical Code®, Article 312 addresses cable bend space for power equipment in cabinets where conductors enter or exit through the wall of an equipment enclosure in Table 312.6(B). For example, it specifies a minimum space for 300 AWG or kcmil cable as follows: 1

• 10 inches (254 millimeters) for terminals served by one or two conductors

• 11 inches (279 millimeters) for terminals served by three conductors

• 12 inches (279 millimeters) for terminals served by four or more conductors

Reason 2: Ease of Installation

A second reason to consider cable bend space is that inadequate space can make cables more difficult to install and equipment harder to service. For a transfer switch of a specific physical size, larger diameter cables will require more bending space, which could make it more difficult to route cables to equipment terminals. The extent of this problem depends on factors including the ampacity of the switch relative to the overall size of its enclosure, available pathways for cable entry, and the amount of space within a particular transfer switch for managing cable and accommodating cable bends.

Enclosure Size

In some transfer switch product ranges, a specific ampacity may be offered by different models with differing overall sizes. For instance, in ASCO’s product lines, an ampacity of 600 Amps can be provided by either J-frame or H-frame transfer switches. Because the H-frame uses a larger chassis and enclosure, there typically will be more space for managing cables. Conversely, the J-frame offers, among other differences, a smaller footprint for the same ampacity. Manufacturers may offer larger enclosures or attachable pull boxes to provide additional cable bend space. Where a switch of a specific ampacity is available in only one size, a switch of higher ampacity could be selected to obtain more space for bending and managing power cables.

Available Pathways

Switches may offer options for routing power cables through the top and/or bottom of switch enclosures and locating terminals along the front or rear. The range of available pathways will vary by transfer switch manufacturer, model, and size. For instance, the above-referenced J-frame transfer switch offers terminals for front connection only, while the larger H-frame model provides options for either front-connected or rear-connected configurations. Where a necessary configuration is unavailable, some manufacturers offer custom engineering services. Read the ASCO document entitled Benefits of Custom-Engineered Transfer Switches for additional information. 2

Available Volume

Larger transfer switches generally offer more space for bending and routing cables. Nevertheless, applications involving many cables can present unique challenges. Where cables are very dense, it may be difficult to coordinate their respective bending, routing, and termination. Once installed, it also may be difficult to access them for visual or thermal inspection of connections, tightening of cable connections, or for service of any nearby components. To alleviate cable crowding, pull boxes may be added to the sides of equipment frames to provide more space.

Installation Considerations

Cable bend space should be considered for both new installations and system upgrades. Providing sufficient room to bend, route, and terminate cables can streamline both new installations and retrofits. If power system upgrades or expansions may be needed, then providing extra room could mean the difference between future adaptability or obsolescence.

Notably, specifiers also need to consider the adequacy of the aforementioned NEC requirements. Table 312.6(B) provides bend space values for applications that use one through “4+” cables per terminal. Without further consideration, this guidance could prove insufficient. Figure 1 shows the terminals for an uninstalled 4000 Amp transfer switch configured with lugs for fifteen 300 kcmil power cables per terminal. Because this is a four-pole switch, 120 cables will be installed on the back of this device. The NEC specified bend space may be insufficient for such a large number of cables. Consequently, specifiers can ensure that cable space and routing issues will not be problematic by consulting transfer switch providers and installers before finalizing a cable termination configuration.