Supervisory Control and Data Acquisition (SCADA) Human Machine Interface (HMI) systems are used in monitoring equipment across many industries and applications, including emergency power. This article describes SCADA HMI generally and summarizes how it is often used in backup power systems, including applications served by ASCO Power Technologies equipment.

SCADA HMI Description

Historically, SCADA systems have enabled the monitoring and control of electrical systems through discrete communication channels. Over time, the information managed by SCADA systems increased in scope and complexity, resulting in the increasing integration of HMI and SCADA technologies. Today, SCADA HMI functionality enables advanced graphical display and interaction for monitoring equipment and systems in many industries and applications.

SCADA HMIs process user inputs to set operating parameters in electronically controlled equipment. They enable the adjustment of priorities, time delays, operating modes, test features, and more. They also monitor the control system and power switching equipment, and alert users when problems are detected in Programmable Logic Controllers (PLCs), circuit breakers, protective relays, generators, and other devices. In addition, SCADA HMI maintain logs that enable users to view events and alarms as they occurred. SCADA HMI also supports system testing and is responsible for monitoring building power metrics and displaying them to users.

SCADA HMI collect and process real-time data from power devices, display it through one or more HMI devices, and provide real-time alarms and notifications of operating conditions. In some applications, SCADA HMI systems initiate and supervise responding actions automatically.

Purpose and Application

SCADA HMI systems monitor, alarm, and control operations in industrial plants, transportation facilities, water infrastructure, electrical utility grids, and more. They process data from pumps, switches, and electrical or electromechanical devices and execute tasks based on the data received. For example, SCADA HMI systems commonly collect data from alarm devices; filter and categorize alarm inputs; then forward alarms to other equipment, to notification systems, or to users through SMS or email messages. They can organize and present alarm data in ways that enable operators to become aware of and respond to important situations quickly.

SCADA Functions

In backup power applications, SCADA HMI systems collect analog or digital data from power devices for processing and store it for future reference. SCADA systems process the information to produce worded messages, data tables, historical logs, or graphic outputs for display. Human operators respond to and interact with the equipment through the SCADA HMI systems.

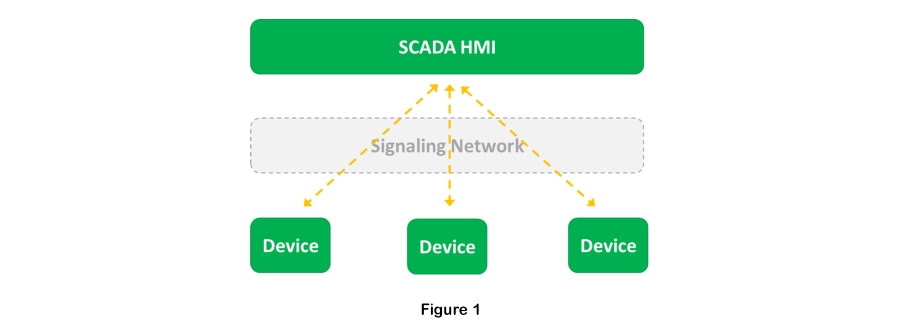

SCADA HMI can interact with a broad range of power devices. These include switchgear, automatic transfer switches, protective relays, generator controllers, circuit breaker trip units, power meters, and more. Figure 1 provides an overview. Backup power equipment control, monitoring, testing, and diagnosis would be difficult to complete without the functionality that SCADA HMI provides.

SCADA HMI Description

Historically, SCADA systems have enabled the monitoring and control of electrical systems through discrete communication channels. Over time, the information managed by SCADA systems increased in scope and complexity, resulting in the increasing integration of HMI and SCADA technologies. Today, SCADA HMI functionality enables advanced graphical display and interaction for monitoring equipment and systems in many industries and applications.

SCADA HMIs process user inputs to set operating parameters in electronically controlled equipment. They enable the adjustment of priorities, time delays, operating modes, test features, and more. They also monitor the control system and power switching equipment, and alert users when problems are detected in Programmable Logic Controllers (PLCs), circuit breakers, protective relays, generators, and other devices. In addition, SCADA HMI maintain logs that enable users to view events and alarms as they occurred. SCADA HMI also supports system testing and is responsible for monitoring building power metrics and displaying them to users.

SCADA HMI collect and process real-time data from power devices, display it through one or more HMI devices, and provide real-time alarms and notifications of operating conditions. In some applications, SCADA HMI systems initiate and supervise responding actions automatically.

Purpose and Application

SCADA HMI systems monitor, alarm, and control operations in industrial plants, transportation facilities, water infrastructure, electrical utility grids, and more. They process data from pumps, switches, and electrical or electromechanical devices and execute tasks based on the data received. For example, SCADA HMI systems commonly collect data from alarm devices; filter and categorize alarm inputs; then forward alarms to other equipment, to notification systems, or to users through SMS or email messages. They can organize and present alarm data in ways that enable operators to become aware of and respond to important situations quickly.

SCADA Functions

In backup power applications, SCADA HMI systems collect analog or digital data from power devices for processing and store it for future reference. SCADA systems process the information to produce worded messages, data tables, historical logs, or graphic outputs for display. Human operators respond to and interact with the equipment through the SCADA HMI systems.

SCADA HMI can interact with a broad range of power devices. These include switchgear, automatic transfer switches, protective relays, generator controllers, circuit breaker trip units, power meters, and more. Figure 1 provides an overview. Backup power equipment control, monitoring, testing, and diagnosis would be difficult to complete without the functionality that SCADA HMI provides.